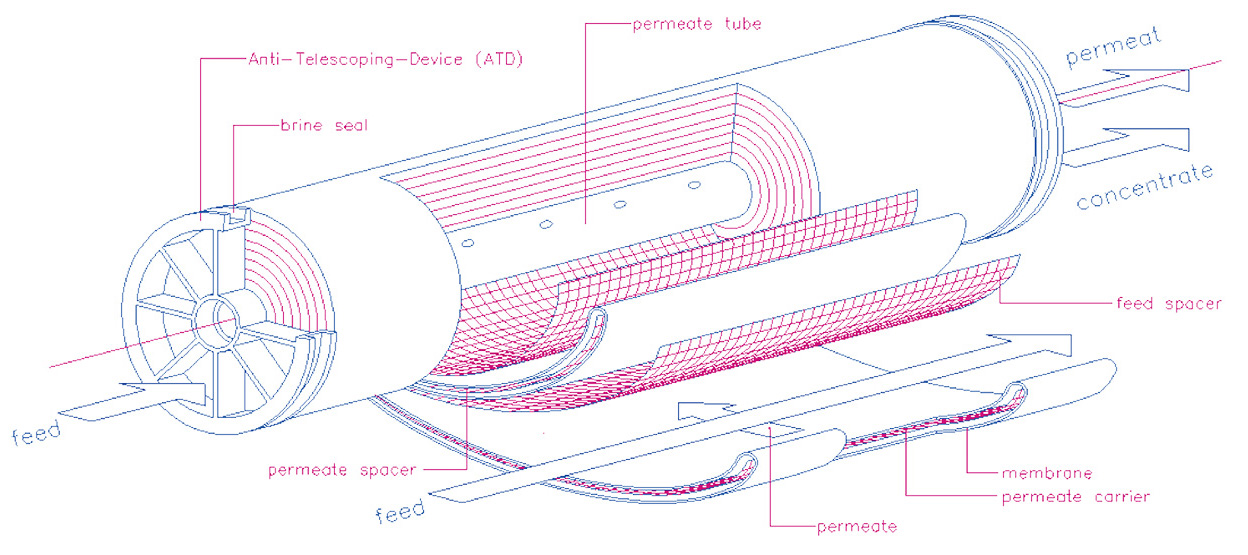

The Spiral wound membrane is formed by winding a flat sheet membrane , feed spacer, permeate carrier and center permeate tube components into a spiral wound membrane module. This design significantly increases the packing density and separation efficiency of the membrane, while facilitating installation and maintenance. The operating principle is based on pressure-driven, selective separation of impurities, solutes or solvents from a solution by means of membrane materials with different pore sizes (MF, UF, NF, RO)

Product Features

Compact Structure: The rolled membrane packs a large membrane area into a small space with high stacking density. This allows for high - capacity treatment in a limited space, suiting water treatment and separation processes of all scales.

High Separation Efficiency: Based on different membrane materials and pore - size designs, it efficiently separates various substances. It has excellent removal of salts, organic matter, and microorganisms in water, with high desalination and retention rates.

Broad Operating Pressure Range: The operating pressure can be selected according to application needs and material properties. Rolled reverse osmosis membranes typically operate at 1 - 10 MPa or higher, while rolled ultrafiltration and microfiltration membranes operate at 0.1 - 0.6 MPa.

Strong Adaptability: By choosing different membrane materials and adjusting structure and performance parameters, rolled membranes can adapt to diverse materials and conditions, including different water qualities, temperatures, and pH levels.

Low Operating Cost:Compared to traditional separation methods like distillation and extraction, membrane separation usually doesn't require heating or phase - change processes. It has low energy consumption and simple operation, resulting in relatively low maintenance costs.

Customization Support:For the wide - ranging applications of rolled membranes, UNISOL provides a full spectrum of membrane types (MF, UF, NF, RO). Membrane modules are available as standard products, and can also be fully customized for customers.

Industry Applications

Food & Beverage Industry: Applied in fruit juice clarification and concentration, milk degreasing and concentration, beer clarification, and enzyme purification.

Pharmaceutical Industry: Used for separating and purifying drug intermediates, protein separation in biopharmaceuticals, antibiotic concentration, and removing pyrogens from drug solutions.

Industrial Wastewater Treatment: Treats electroplating, printing and dyeing, and chemical wastewaters to recover heavy metal ions, remove organic matter, and enable water reuse.

Seawater & Brackish Water Desalination: Removes salt and impurities from seawater to supply fresh water for coastal areas and islands.

Chemical Production: In petrochemical and fine - chemical fields, it separates, concentrates, and purifies materials, like separating organic solutions and recovering catalysts.

| E-coat | Standardization of milk | Cream cheese production |

Concentration of protein and gelatin | Whey concentration processing | Clarification of cheese brine |

| Enzymes, fermentation broths | Clarification of soy sauce | Acid recovery |

| Caustic recovery | Industrial water | Oil / Water emulsions |

Product Types & Codes

Module: FG-UPV200-8040-C

FG Design / Application | UPV200 Membrane Type / MWCO | 8040 Diameter / Length | C Feed spacer | |

| SN Sanitary Design SH Sanitary Design ID Industrial Design EC Electro coating PD Pharmaceutical Design FG Fiberglass CR Caustic Resistant AR Acid Resistant HP High Pressure Resistant TR Temperature Resistant ------------ Example: FG Fiberglass | UPS Polyethersulfone USP Polysulfone UPV Polyvinylidene MPV Polyvinylidene NFDK/NFDL Piperazinamide SW3013 Polyamide ------------ Example: UPV200 MWCO 200kDa | 25 40 38 38 40 40 43 33 63 38 80 38 80 40 83 38 ------------ Example: 8040 Length 40inch | A 34mil (parallel) B 31mil (diamond) C 46mil (diamond) D 51mil (parallel) E 65mil (diamond) F 80mil (diamond) G 80mil (parallel) H 60mil (parallel) J 28mil (diamond) K 20mil (diamond) L 24mil (diamond) M 34mil (diamond) * 1 mil = 0,001 inch* ------------ Example: C 46mil diamond | |

Advantages

FDA Compliant Materials |

Wide range of membrane types |

High temperature resistance |

High pH, solvent resistance |

Great mechanical strength |

Customization |

Read more about spiral wound membranes: UNISOL Spiral Wound Elements Brochure