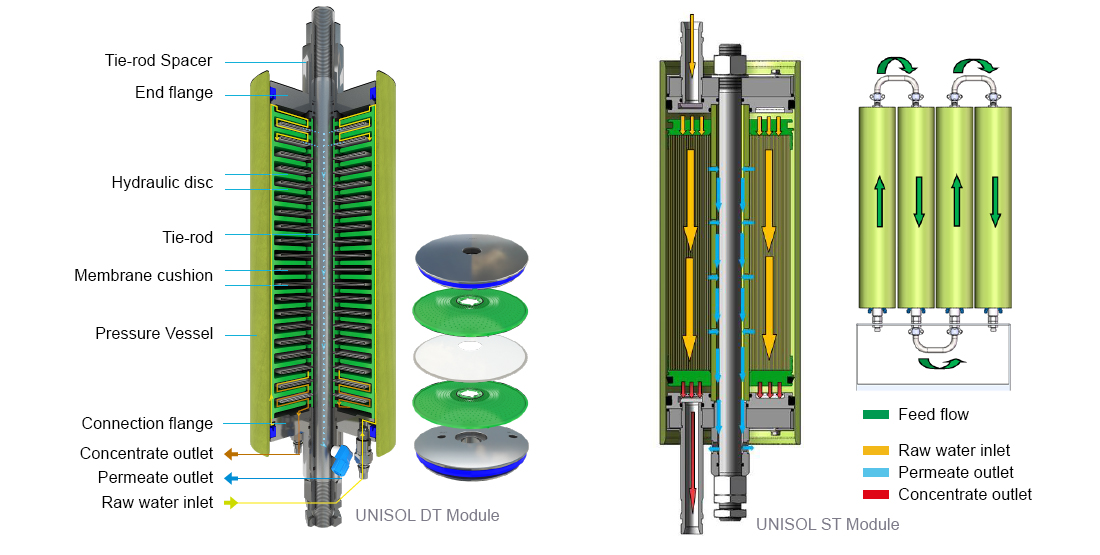

DT Membrane Module

DTRO is a significant advancement in membrane technology. It can operate cost - effectively during separation, even with high turbidity and SDI. Its main applications cover waste leachate treatment, industrial wastewater treatment and zero - discharge, as well as seawater and brackish water desalination.

Anti - fouling: With an open - flow - channel design and wide feed - liquid flow channels, it prevents physical blockage. The convex - point - supported hydraulic disc creates a turbulent flow, minimizing membrane surface scaling, fouling, and concentration polarization.

Long - lasting Membranes: It reduces membrane scaling, eases fouling, and extends cleaning intervals. The DT's structure and hydraulic design facilitate cleaning, with excellent post - cleaning flux recovery, thus prolonging membrane life.

Easy Operation & Maintenance: The standardized membrane module is easy to disassemble. Any membrane or component can be inspected and maintained easily. It can function with fewer membrane sheets and discs when components are short. All maintenance is on - site. Filter membranes can be replaced individually, reducing replacement costs.

High Concentration Ratio: It offers multiple operating - pressure levels and is among the highest - pressure - rated membrane modules in industrial use. In high - concentration applications, the solid content can exceed 25%.

ST Membrane Module

ST membrane technology is a novel structural membrane module tailored for leachate and high - salinity wastewater treatment. It features a roll - membrane structure, with the membrane sheet using industrial anti - pollution RO or NF membranes. The grid channel has a parallel grid structure distinct from common roll membranes, enabling long - term stable operation in areas where general roll membranes fail.

Anti - pollution: The open - flow - channel design and unique grid structure ensure smooth material and liquid flow, resisting blockage. They reduce membrane - surface scaling, fouling, and concentration polarization. This makes ST membranes highly adaptable to high - concentration, high - COD wastewater, applicable in treating landfill leachate and high - salt industrial wastewater.

High Flux: ST membranes combine DTRO's high - pressure resistance and anti - pollution advantages with the large flux of traditional rolled - reverse - osmosis RO. The larger membrane area and optimized flow - channel design allow for more water treatment in the same time, enhancing treatment efficiency.

High Desalination Rate: Under standard test conditions, the desalination rate of ST membranes can reach 99% with stable performance. They effectively remove salts from water, ensuring the produced water meets high - quality standards for various applications.

DT/ST Applications

Industrial Wastewater Treatment: Capable of treating diverse industrial wastewaters like electroplating, textile, printing and dyeing, chemical, coal chemical, coking, and iron - steel wastewaters. It effectively eliminates organic matter and heavy metals, enabling wastewater to meet discharge standards or be reused.

High - Salt Wastewater Treatment: Efficiently removes salt from high - salt wastewater, with excellent treatment results for high - salinity landfill leachate and concentrated brine, achieving wastewater reduction and resource utilization.

Drinking Water Treatment: Effectively filters out suspended solids, bacteria, viruses, organic and inorganic salts in water, enhancing water quality to meet drinking water standards.

Seawater Desalination: Used for seawater desalination, removing salt and impurities to obtain high - quality fresh water, providing a reliable water source for arid regions.

Food Processing: Applied in fruit juice, alcohol, and dairy product concentration, improving product quality and yield.

Pharmaceutical Manufacturing: Utilized for water treatment in pharmaceutical production, such as for injection water and filling water, ensuring product quality and safety.

Additional Applications: Waste leachate treatment, material high - concentration processes, chemical wastewater handling, wastewater desulfurization, high - solids scenarios, offshore desalination, and industrial wastewater reduction/zero - discharge.

DTRO Module List

Module | Max. Operating Pressure | Effective Membrane Area | Temperature Max. | pH range | Wet Weight | Rejection | Flux |

90bar | 9.405m² | 45℃ | 3-11 (Operating) 2-12 (CIP) | 70kg | 99% | 250L/h | |

120bar | 100kg | 98% | 200L/h | ||||

160bar | 100kg | 98% | 200L/h |

STRO Module List

Module | Max. Operating Pressure | Effective Membrane Area | Temperature Max. | pH range | Wet Weight | Rejection | Flux |

90bar | 25m² | 45℃ | 3-11 (Operating) 2-12 (CIP) | 60kg | 98.50% | 500L/h | |

90bar | 30m² | 70kg | 98.50% | 600L/h | |||

120bar | 30m² | 100kg | 98.50% | 500L/h |

Read more about DT/ST modules: UNISOL DTRO&STRO Brochure