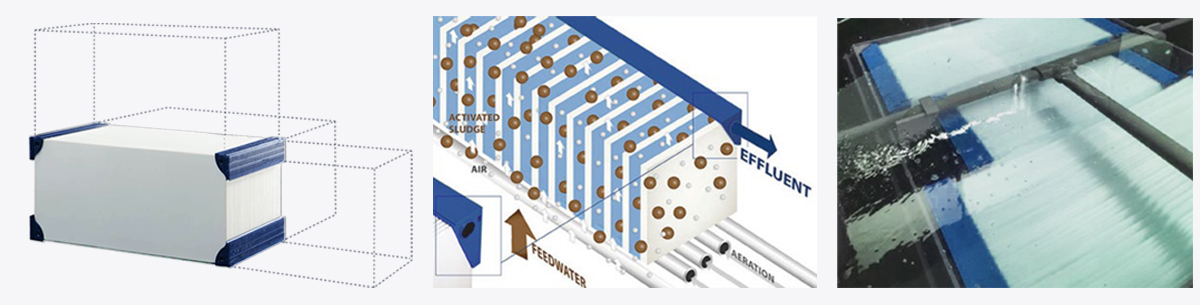

The modular concept of the MYTEX.BLOCKs allows for an easy installation of the complete module with a lifting gear or the assembly of the module on site in case space is a restriction. The stackable MYTEX.BLOCKs are perfectly suitable for a simple expansion or the complete module replacment in an existing plant.Customer-specific sizes are available on request.

In the last decade Membrane -Bio -Reactors (MBR) have become a State of the Art technology in wastewater treatment. The application of submerged MBR membranes increase the effluent quality and the efficiency of a waste water treatment plant within the activated sludge treatment.

UNISOL's MYTEX Membrane Modules combine flat membrane technology with a unique and innovative design concept - stackable membrane modules. These blocks can be stacked side by side or in any vertical or horizontal direction, allowing for a high flexibility in size for the MYTEX module.

MYTEX RETROFITS Solutions

Are you looking for a replacement or an alternative for your existing membrane system? When exchanging or upgrading existing membrane systems, companies have always been bound to the original membrane supplier. Certainly, manufacturers are aware of this. Therefore, prices for spare parts are high.

With our MYTEX RETROFITS we are able to replace almost every membrane module available in the market. Often, existing base frames and aeration systems can remain unchanged and only the membrane part is replaced by specially manufactured membrane blocks. This keeps replacement and conversion costs to a minimum and reduces your dependence on a single membrane supplier.

We would be pleased to equip your existing plant with new UF and MF modules and to individualize our filtration products according to your requirements.

Typically, no changes to the operating mode are necessary, as MYTEX modules are compatible with all common operating modes:

Gravity filtration with relaxation or with backwash via elevated tanks.

Filtration and back flush with reversible permeate pump

Filtration with centrifugal pump without backwash (relaxation only)

Application of various chemical cleaning strategies

Aeration with fine bubble or coarse bubble aeration possible

Application Fields

Urban Wastewater Treatment: Treats urban domestic wastewater, removing pollutants like organic matter, nitrogen, and phosphorus. The effluent meets reuse standards for urban greening irrigation, road washing, and landscape water replenishment, thus recycling water resources.

Industrial Wastewater Treatment: In pharmaceutical, printing - dyeing, papermaking, and chemical industries, it effectively handles high - concentration, hard - to - degrade industrial wastewater. Removes organic matter and heavy - metal ions, ensuring wastewater meets discharge or reuse standards and reducing environmental pollution.

Water Reuse: In hotels, hospitals, schools, and residential communities, domestic sewage is treated for reuse in toilet flushing, car washing, and laundry. This improves water - resource efficiency and cuts fresh - water demand.

Rural Wastewater Treatment: Well - adapted to rural decentralized wastewater treatment. Can flexibly design and install a submerged flat - plate MBR system based on rural wastewater characteristics and treatment needs. Achieves on - site wastewater treatment and compliant discharge, enhancing the rural water environment.

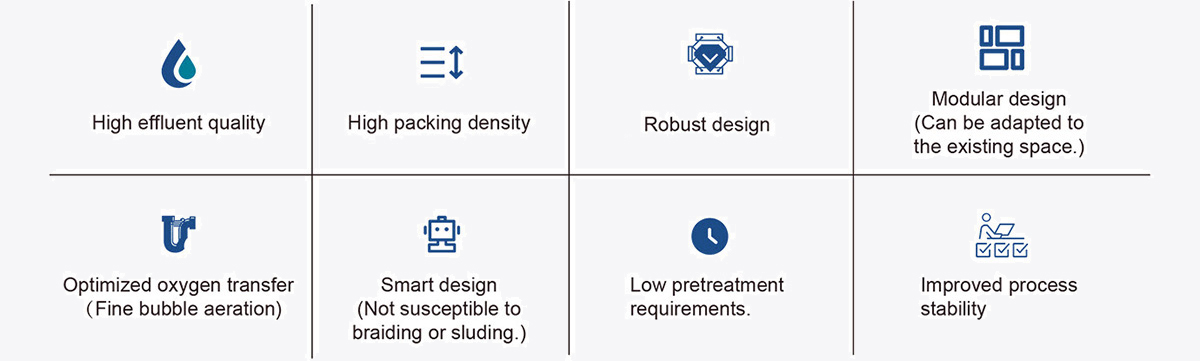

Advantages

MBR Model Specification

Module | Membrane area (m²) | Dimensions (mm) L*W*H | Typical design air flow rate |

52 | 1426*757*1203 | 47 Nm3/h | |

104 | 1426*757*1724 | 47 Nm3/h | |

156 | 1426*757*2253 | 47 Nm3/h | |

208 | 1426*757*2778 | 47 Nm3/h | |

312 | 1543*1295*2344 | 96 Nm3/h | |

416 | 1543*1295*3016 | 96 Nm3/h | |

520 | 1543*1295*3543 | 96 Nm3/h | |

624 | 1543*1295*4068 | 96 Nm3/h |

Operation Data

Parameters | Specification |

Max.TMP during filtration | 800mbar |

Max. TMP during backwash | 300mbar |

Operating/Cleaning temperature | < 50°C |

pH range for chemical cleaning | 2-11 |

Recommended MLSS for continuous operation (g/L) | ≤15 |

Read more about UNISOL MBR modules: UNISOL MYTEX MBR Modules Brochure